Portable direct push system

When an owner wants to renovate an existing structure, the geotechnical design engineer often must evaluate the strength and stiffness of the bearing soils. Unfortunately, the structure usually blocks access for conventional soil testing equipment, and the engineer has difficulty measuring the properties of these soils. We have developed a portable direct push system that can move through a 32-inch wide door opening to access the ground floor concrete slab next to the structure’s footings. Our system only needs headroom of 7 feet to effectively operate. After coring a 4-inch diameter hole through the slab, our system bolts to the slab using eight (8) ½-inch diameter bolts and Hilti concrete anchors. To make sure that the bolt holes align with the push system, we use a steel template to position the holes. By hammer-drilling two corner holes first, we bolt the template to the floor so that it cannot shift, while we drill the other 6 holes. Our hydraulic power pack uses a 240 volt/30 amp circuit power supply. While we often use a generator to power it, we prefer a wired outlet (4-prong) inside the building (Figure 1). Our portable system has a thrust capacity of 10 tons, and we can perform either CPT or DMT with it to measure the soil’s properties. Poor quality concrete will lessen the thrust capacity.

Figure 1: Photos of electric outlet and plug for electrician to wire prior to mobilizing to site

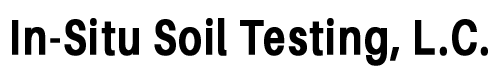

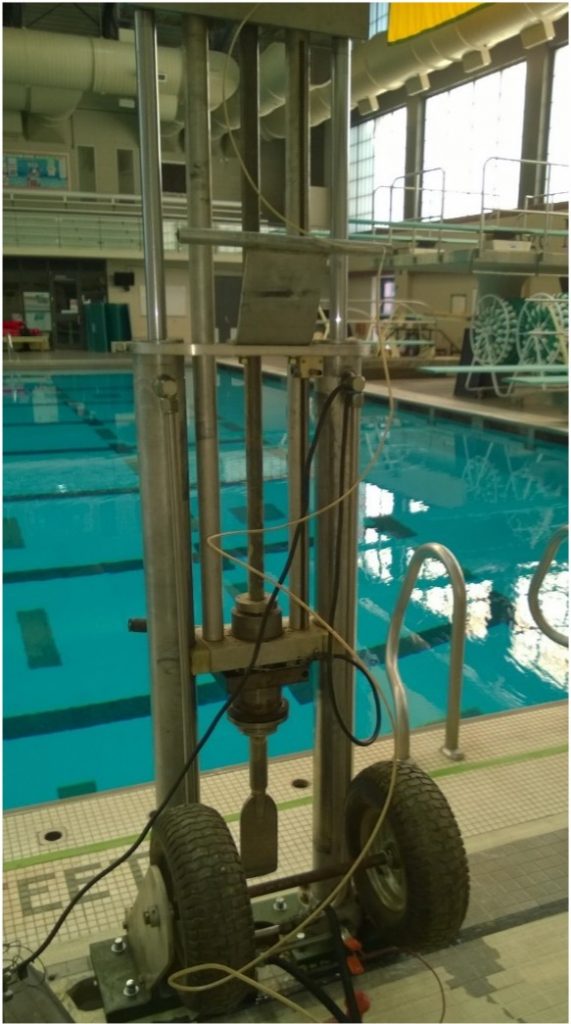

Photos of the portable push rig and automated dilatometer control unit are presented below:

Left: In basement of Lynchburg Virginia Hospital

Right: Basement of Museum of the American Educator in Washington D.C.

Portable push rig for dilatometer testing at Phillips Hall at James Madison University in Harrisonburg, Virginia