Ko Step Blade Test

Benefits of Ko Step Blade Test:

- Measures the soil’s horizontal stress in place for soft to stiff cohesive soil and loose to medium dense cohesionless soil

- Immediate results save the owner and engineer time and money

K0 Step Blade (KSB): While engineers can estimate the vertical stress of soil relatively accurately, they cannot estimate the horizontal stress. The coefficient of horizontal stress, K, ranges from 0.2 to 6 times the vertical stress (Schmertmann, 1985). Soils resist applied vertical stresses in one vertical and two horizontal dimensions, emphasizing the importance of the horizontal supporting stresses.

Unfortunately, engineers struggle to measure horizontal stresses. When we drill a hole, we remove them. When we push a device into the soil, we tend to increase them in looser soils and decrease them in denser soils. Undisturbed soil sampling causes too much disturbance for the engineer to measure horizontal stresses with laboratory tests.

The engineer applies pressure to each step membrane using the control unit (Figure 2). A patented system applies increasing gas pressures to inner and outer radial sides separated by a rubber O-ring for each cell, with a slight differential pressure between them. When the cell membrane has the same pressure as the horizontal earth pressure, it lifts off or separates from the O-ring and the differential pressure between the inner and outer sides goes to zero. The engineer measures and records this horizontal earth pressure for the cell at that step. He/she repeats measuring and recording horizontal pressures for the other cells in a matter of minutes. The driller pushes the blade 10 centimeters or one step length and the engineer measures the horizontal earth pressure for all four cells to obtain closely spaced pressure determinations. The boring then is advanced to obtain the next set of readings.

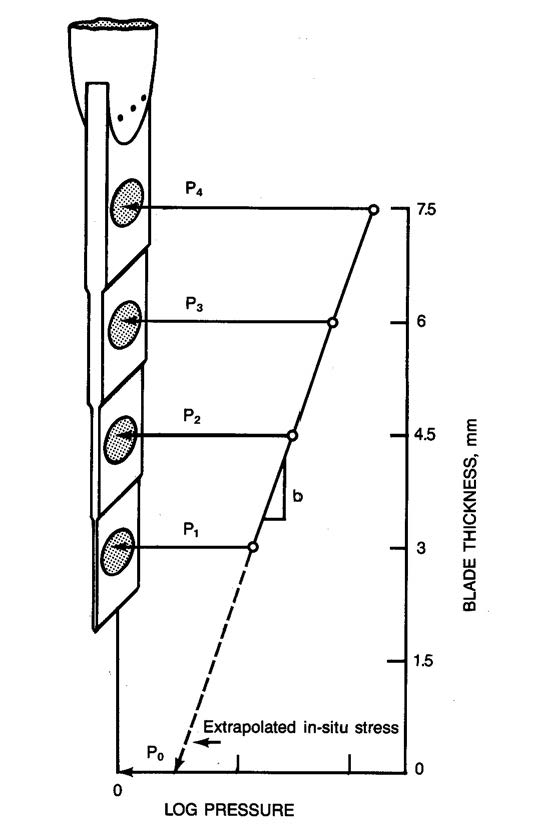

Dr. Dick Handy (1982) invented the K0 step blade to measure this difficult to obtain soil parameter. The blade contains four steps starting from thin to thick from its bottom to top (Figure 1a [front] and 1b [rear]). Based on finite element analyses, a stainless-steel stiffener could be placed along the back of the K0 blade and the measured horizontal stresses would not lose any accuracy. This stiffener also provides convenient routing for the air lines.

Figure 1a, 1b: Front and rear view of K0 step blade

Figure 2: K0 step blade control unit

Even the thinnest step causes disturbance to the horizontal stresses when the blade pushes into the soil. By plotting the blade thickness versus the log horizontal stress, engineer extrapolates the horizontal stress at a blade thickness of zero (Figure 3), computing the horizontal stress at rest or a zero-thickness step. Handy (2008) documents +10% accuracy for this method. (Note that the maximum 7.5‑mm‑thickness of the Ko step blade halves that of the 15‑mm‑thick dilatometer blade.)

US DOT-FHWA sponsored the research at Iowa State University. Handy, et. al. 1990 document field experience with the K0 step blade test for the Transportation Research Board. Handy 2004 provides instructions for performing the K0 step blade test. An Excel spreadsheet processes Ko step blade data.

Figure 3: Computing the horizontal pressure